What We Have Done

-

Bulwer Full Fuels Terminal Project

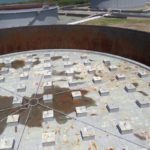

The Bulwer Full Fuels Terminal Project has been set up by BP and involves the refurbishment, upgrade and conversion of redundant crude and product tanks, ranging 30m to 86m in diameter, to store a range of imported refined fuels.

OTAC was engaged as the tank specialist company to carryout inspections and develop detailed scope of work documents complete with drawing and reference packages and budget cost estimates. The project also included the preliminary design for new Ethanol and Bio Diesel tanks, together with ITB documentation and budget pricing.

General Requirement documents were also developed to ensure alignment and conformance to API Codes of Practice, mandatory and consistent tank inspections and testing, coating applications, safe work practices, material and equipment standards.

OTAC has remained the tank specialist and client advisor as the various project stages progress through the Capital Value Process and into their Execute stages. -

Bulwer Jet Terminal Project

The Bulwer Jet Terminal Project was developed to convert the former Bulwer Island Refinery to a jet fuel import facility to service the nearby Brisbane Airport. As Tank Manager for this project, the role encompassed the development of tank refurbishment and upgrade scopes of work, cost estimates and project schedules for 9 tanks, ranging 30m to 45m diameter, to be converted to Jet service and meet the requirements of the Project Basis of Design. Initial work included the establishment of work specifications, definition and responsibilities of contracted work, formalizing the Invitation to Bid documentation, followed by selection of a suitable vendor.

Work, which successfully met all budget and schedule constraints, included the replacement of tank foundations, removal of existing IFR’s, installation of new floating suction systems, additional product and water sampling systems, foam and cooling water system upgrades, together with routine repairs and full roof/floor replacements. -

Kutubu Refinery Project

The Kutubu Refinery tank project was a Monadelphous/Jacobs joint venture for Oil Search in the New Guinea Highlands.

OTAC was engaged as the tank specialist company to carry out a review of existing inspection documentation and develop a full API 653 assessment for the refinery Residuum Storage tank. The project included addressing present corrosion issues and mechanisms, recommending mitigation strategies, developing the scope of repair options, execution processes and manhour estimates.

The project was extended to carry out a review of relocating the tank which included analysis of the tank process and piping configurations and utility tie-ins. -

Atmospheric Storage Tank Construction & Maintenance

Storage tank construction and maintenance were the building blocks of OTAC. Experience in tank maintenance was built from years of executing a program of parallel turnarounds of multiple tank projects on a continual basis.

Experience in the management of tank construction was contributed to roles as Project Manager for the successful delivery of tank construction projects ranging from 30m diameter petrol tanks to 86m diameter crude oil storage tanks.

Tank projects included civil and foundation work, associated piping systems and infrastructure and encompassed accountability from front end engineering design to execute/commissioning stages, while ensuring code compliance throughout the project and adherence to budgets and contractual conditions. -

Tank Inspections

OTAC has been engaged by numerous downstream oil companies to carry out both on-stream and off-stream visual inspections to product storage tanks and provide an evaluation of the results in accordance with the applicable criteria of API 653.

In conjunction with previous NDT inspection data, repair scope documents were issued addressing immediate and future integrity issues, allowing tank service to continue and meet client service life cycle expectations. -

Storage Tank Upgrade Projects

OTAC offers consultancy services backed by experienced professionals with a consistent track record of successfully delivering tank upgrade projects from the concept and detailed basis of design through to execute, commissioning and return to service.

All upgrade projects have been successfully delivered, ensuring alignment of project deliverables to business requirements of HSE, risk, cost effectiveness and adherence to applicable codes and standards.

OTAC personnel have managed the construction of atmospheric storage tanks, from 1Ml to 90 Ml in size, ensuring build quality and adherence to client contractual requirements and compliance to code.

We work closely with other professional tank service equipment suppliers to ensure cost effectiveness and suitability of materials to meet the constraints and design requirements of the specific project.